Let’s take a look at a simple ohmic heater as might appear in a MEMS flow-sensor. An example is the FLS122 (FLUSSO, Cambridge, U.K.) which is a MEMS air velocity sensor in a surface mount package. The FLUSSO website states that the heater is based on a lithographically patterned tungsten wire. Either side of the wire is temperature sensor and during air flow, heat will be preferentially transported in one direction, resulting to a greater temperature rise downstream of the heater. The difference in the upstream and downstream temperatures enables the air velocity measurement.

A challenge in making such a heater is thermally insulating it from the substrate: the heat should flow into the liquid above not the substrate beneath. One way of achieving this is to perform the MEMS fabrication using a silicon-on-insulator (SOI) process, so that the heater lies on a silicon dioxide membrane with a relatively high intrinsic thermal resistance.

Setting up the simulation

Here, we build a model for a flow-sensor, related to the FLUSSO design, but in this case sensing the flow of liquid in a flow-cell. A flow-channel (50 µm height) containing water lies above a SOI MEMS chip. The die contains a silicon-dioxide membrane (4 µm thickness, 500 µm diameter). Above the flow channel, there is a glass lid. And, either side of the membrane, is the silicon substrate. In the flow-channel, the water is set to flow with a parabolic velocity profile, corresponding to laminar flow, and parameterised by its maximum velocity. The laminar flow assumption is likely safe due to the low height of the flow-cell and correspondingly low Reynolds number.

The heater is a simple metallic line (width 25 µm, height 1 µm) supported by the membrane. Each of the 10 mesh elements (1 µm x 2.5 µm) making up the heater dissipates a power of 1 W/m. Assuming 500 µm length, the total power dissipation is 5 mW. This sounds about right for a lithographically fabricated heater element. In the actual implementation the current density in the heater would have to be considered (due to electromigration) and would place an upper limit on the power dissipated.

Not shown here, but likely present in an actual device, are a pair of thermometers at the surface of the chip at x = +- 200 µm. They are placed on the membrane giving a larger thermal response than if they were placed on the silicon substrate.

Looking at the results

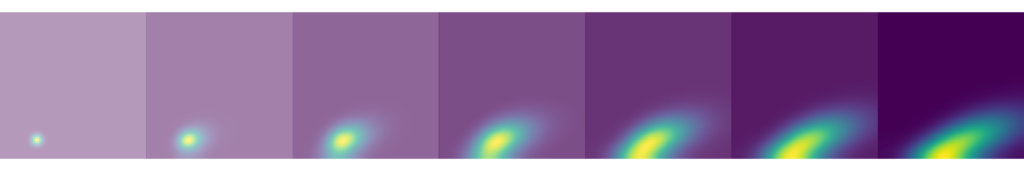

Below, we show a colourmap of the temperature field in the flow-cell at flow-velocity of 10 mm/s. The resulting temperature distribution is skewed in the direction of flow, as expected, and there is a maximum temperature rise of just over 10 K. The y-axis in the following figure is scaled, so that just the temperature rise in the liquid is plotted.

Here we look in a little more detail at the skewness of the temperature distribution on the surface of the chip as a function of the peak flow-velocity. As expected the distribution moves from being symmetric at no-flow to being highly asymmetric at the highest flow-velocities.

Analysing the device as a flow-meter

In order to simulate the use of the device as a flow-meter let’s determine the temperature (TR, TL) at each of the thermometers positioned 200 µm either side of the heater. At no-flow the temperature distribution is symmetric suggesting that we take our signal as the difference between these temperatures, (TR – TL). Plotting this difference as a function of flow-rate results in the following graph, which shows linearity at least up to a velocity of 5 mm/s.

It is interesting to look at how the thermal resistance of the heater changes. Below, the thermal resistance is plotted as a function of flow-velocity and we see that it is more or less constant at the lowest velocities then appears to show a quadratic dependence as the velocity increases.

This simple simulation and correspondingly simple analysis have already raised many questions. What is the effect of the membrane width, oxide thickness, flow-channel height, location of the thermometers? These can all be parametrically varied and the effects analysed. How linear exactly is the response of the difference in temperature signal? It would be possible to include more detail in the model, for example, adding all the layers present in a commercially available MEMS processes. The performance of the thermometers could be included in the model allowing a signal to noise analysis of the flow-meter’s performance. And ultimately, the simulation could feed into the manufacture of a prototype, hopefully saving time and money.

Implementation

The methodology was to use a finite difference method with a structured grid for the solution of the advection-diffusion equation. In order to implement the spatially varying thermal conductivities, the thermal conductivity grid was staggered from the temperature grid by half a unit-cell. The code for this simulation is available on GitHub. It is written in Python, run from a Jupyter notebook and makes use of a SciPy method for the solution of the sparse matrix equation. A Dirichlet boundary condition of ΔT = 0 is used throughout the simulation.